Innovations in Spring Coiling: The CNC 45 Camless Machine

- Minya Hou

- Nov 4, 2025

- 3 min read

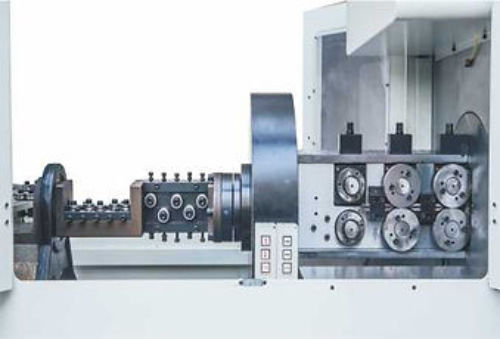

In the realm of manufacturing, the CNC 45 Camless Spring Machine stands out as a revolutionary advancement. This versatile wire coiling and bending machine is specifically designed to produce car springs and a variety of other products with remarkable efficiency. By incorporating a camless design, it significantly enhances operational efficiency, reducing both processing time and costs. Crafted from durable materials, the machine boasts exceptional durability and wear resistance, making it a reliable choice for manufacturers. Supporting wire sizes up to 5.0mm, the CNC 45 is equipped with 12 fully synchronized axes, offering high precision that is particularly beneficial for producing torsion, compression, and automotive springs. As a leading spring coiling machine manufacturer, Dongzheng emphasizes customer feedback for continuous improvement, ensuring that their products meet the highest standards of quality and longevity.

Table of contents:

How Double Panel Design Enhances Stability in Manufacturing

The double panel design of the CNC 45 Camless Spring Machine is a key feature that enhances its stability and functionality. This design is pivotal in sectors such as electronics and automotive, where precision and reliability are paramount. By eliminating the need for cams, the machine decreases the complexity of operations, thereby increasing stability during production processes. The double panel design not only supports the machine's robust structure but also minimizes vibrations, ensuring consistent product quality. This feature is particularly advantageous for a spring coiling machine manufacturer aiming to deliver products that meet rigorous industry standards. Stability in manufacturing processes translates to improved product outcomes, and the CNC 45's design is a testament to the importance of structural integrity in modern machinery.

The Importance of CNC Control in Automotive Spring Production

CNC control is a critical component in the production of automotive springs, providing unparalleled precision and efficiency. The CNC 45 Camless Spring Machine leverages this technology to synchronize its 12 axes, ensuring precise movements and consistent results. This level of control is essential for manufacturers who require high-quality springs that meet specific tolerances and performance criteria. The integration of CNC control allows for automated adjustments and real-time monitoring, reducing the likelihood of errors and enhancing productivity. For a spring coiling machine manufacturer, the inclusion of CNC technology is not just a feature but a necessity in maintaining competitive advantage. By utilizing CNC control, manufacturers can achieve faster production rates and superior product quality, aligning with the demands of the automotive industry.

Finding Trusted China Spring Coiling Machine Manufacturers

When searching for reliable spring coiling machine manufacturers in China, it's crucial to consider factors such as reputation, customer reviews, and technological innovation. Dongzheng, a prominent manufacturer, has established a strong reputation for delivering high-quality machines like the CNC 45 Camless Spring Machine. Their commitment to customer feedback and continuous product improvement sets them apart in the industry. Trustworthy manufacturers prioritize durability, efficiency, and advanced features in their machines, ensuring they meet the diverse needs of their clients. For businesses looking to invest in a spring machine, choosing a manufacturer with a proven track record and dedication to innovation is essential. The success of a manufacturer often hinges on their ability to adapt to market demands and provide solutions that enhance production capabilities.

Future Trends in Spring Coiling Machine for Sale

The future of spring coiling machines is set to be shaped by advancements in automation, sustainability, and precision engineering. As manufacturers strive to meet increasing demands for efficiency and environmental responsibility, innovations in spring machine technology are expected to play a pivotal role. The CNC 45 Camless Spring Machine exemplifies the direction of future trends, with features like automatic lubrication and compatibility with probes and cylinders. These advancements not only improve operational efficiency but also contribute to sustainable manufacturing practices. For a spring coiling machine manufacturer, staying ahead of these trends is crucial for maintaining relevance and competitiveness in the market. As technology continues to evolve, manufacturers will need to integrate smart systems and eco-friendly solutions to meet the changing needs of industries worldwide.

In summary, the CNC 45 Camless Spring Machine represents a significant leap forward in spring manufacturing technology. Its camless design, double panel stability, and CNC control are just a few of the features that make it a preferred choice for manufacturers. Dongzheng's reputation as a leading spring coiling machine manufacturer is built on their commitment to quality and innovation. As the industry progresses, future trends will likely focus on enhancing automation and sustainability in manufacturing processes. For businesses seeking reliable and efficient solutions, investing in advanced spring machines like the CNC 45 is a strategic move that promises to yield substantial benefits in production speed and product quality.

Comments